SODAQ Cap Label: The Ultra-Thin Smart Shipping Label (patent pending)

“After scanning the global IoT ecosystem, we found SODAQ to be the only party that could develop such low-power electronics that they could run on a 100mAh battery and be able to send up to 1000 messages over the mobile network. Until today, SODAQ is a unique and trusted supplier for innovative solutions at Bayer.”

Christof Backhaus Tweet

Challenge

To develop a tracking solution capable of streamlining (seed) shipments around the world.

Outcome

A paper-thin smart tracking device (patent pending) capable of transmitting real-time location, motion, and temperature data, while guaranteeing package integrity across the globe.

Impact

The Smart Label project has opened a world of possibilities for an entire range of smart shipping labels. The smart tracker allows shipments to be monitored in real-time without the added labor of mounting a GPS tracking device onto each box.

The Smart Label

The original label designed for Bayer is powered by a printed battery. This 2mm thick battery then powers an iSIM, microprocessor, modem, and antenna while maintaining a thickness comparable to a few sheets of paper. The culmination of all the aforementioned parts can provide readings on the time the asset is opened, the movement the box has been subjected to, and its cell ID location. The smart label communicates LTE-M and NB-IoT networks. We are also developing Sigfox, LoRa, and Bluetooth-based smart labels.

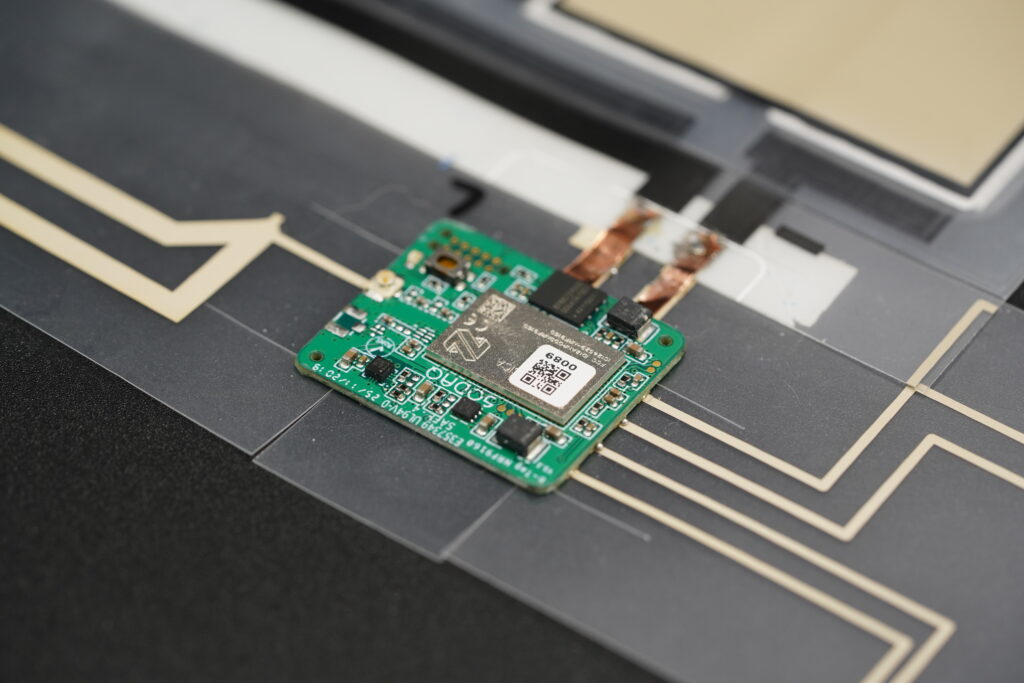

The Cap Label

The Cap label was designed as a multi-use alternative to the Smart Label. The Cap Label utilizes a rechargeable super-capacitor (super-cap) to power an iSIM, microprocessor, modem, and antenna. In addition to LTE-M/NB-IOT, the increased electrical output of the super-cap enables the Cap Label to communicate over 2G. The Cap-Label provides readings on the Location, internal or external temperature, package integrity, and any impact the asset may incur.

The engineering process

Initially, the power consumption feasibility was assessed using preexisting data from SODAQ’s previous developments. We created the first prototypes based on the u-blox R410 module, but eventually opted for the NRF9160 from Nordic as it doesn’t require a separate microcontroller and has outstanding low-power characteristics. SODAQ worked closely to support Elmeric to reach a stage of production for both the battery and the entire label, such that all that SODAQ would need to supply would be a PCB with pre-loaded software to Elmeric.