Patent pending: RF energy harvesting for network sensing.

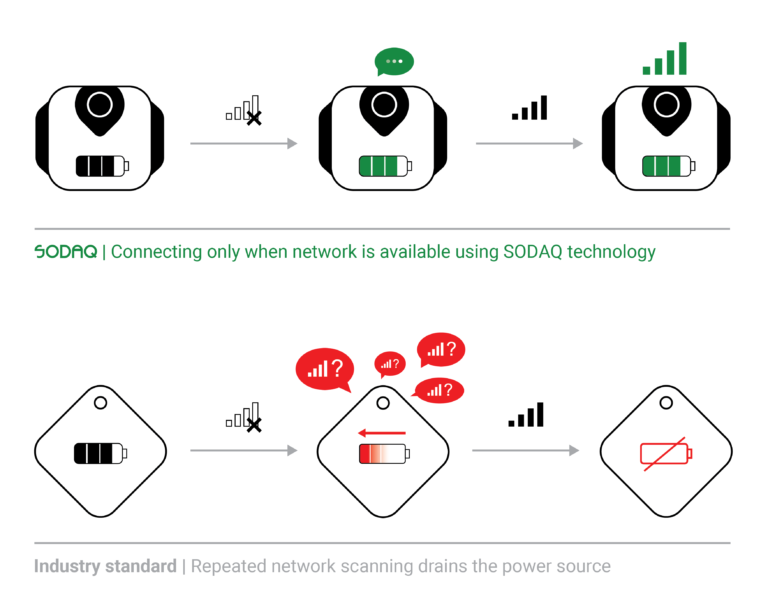

Tracking devices rely on connections with cellular networks all over the world. Searching for a new network can be successful when available – or leaving devices drained without power when there is none. But what if devices could sense whether there is a network, wherever they are, without wasting energy? Now it is possible, with SODAQ’s low-power devices and new patent-pending solution.

Not many things drain the power source of a device faster than trying to connect to a network or send a message when there is no network available. Have you for example ever tried having a phone call from an elevator? Then you probably noticed how hot your phone gets, because it’s trying to find a network. The continuous search for it can use roughly 50 to 100 times more power than sending a message when a network is available. This way, huge amounts of energy are being used up in searching for a network to send or receive data. Batteries or capacitors will die much sooner than they should, which leads to a higher usage of both.

But what if there were a solution to this problem? A sensor needing “zero” power to operate and indicate if there is a cellular network, could multiply the battery life of a tracking device. It saves a considerable amount of energy when the IoT devices search for networks for transmitting and receiving data. Aligned with our belief in low-power and our mission to create world-friendly IoT, SODAQ has been working on a solution. With success.

What is the solution?

The result of our efforts is a sensor based on an antenna, which harvests power to be able to measure if there is an available LTE network. This happens through radio frequency (RF) energy harvesting, as the antenna converts received RF signals into power.

A tracking device can be in a place with or without a connection. Before starting the transmission or opening the modem, the device measures the harvested power on a small capacitor or buffer. The microcontroller measures the voltage on the buffer. If it sees that the buffer is full or above a certain threshold, it can assume there is an available network, and the connection can be made. If the buffer is zero or low, it means that there is no network, and we can skip sending this message.

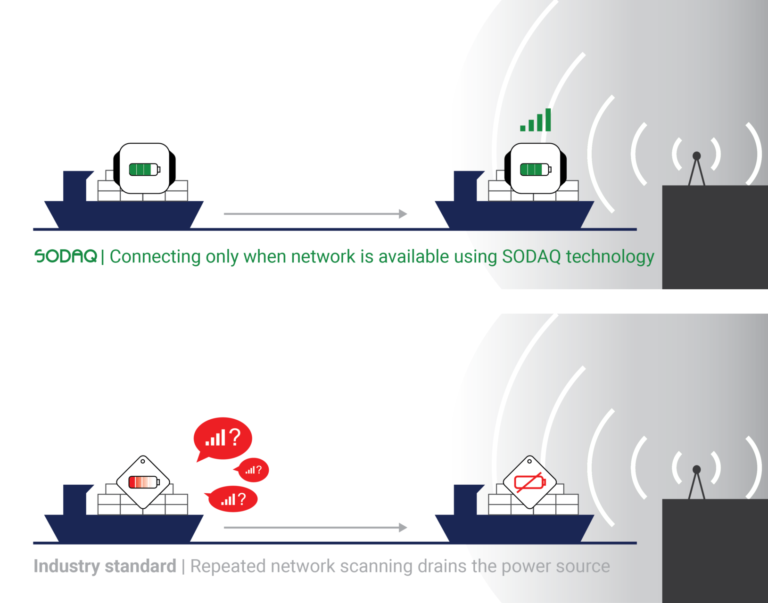

CTO Itay Dagan: “Using SODAQ’s technology, assets such as containers can be tracked anywhere in the world without having to worry about running out of battery power when there is no communication network coverage.”

Why is this solution unique?

Most energy harvesting research is focused on harvesting energy to power up devices or store large amounts of energy. This asks for high input power levels and large directive antennas. In this case, we need far less harvested energy, because we only want to make sure whether there is an available network to send data. When a device can decide there is no network available, it does not need to spend any more energy trying to connect to a network. The result is that the energy of a battery is only used when it is actually needed. This brings us one step closer to a more world-friendly IoT.

The second important advantage of our solution is that you can also measure when you shouldn’t send, for example when the device is inside the airplane when it measures the ADS signal.

Another big advantage is that the on-time of devices is longer when using this solution. When the network does become available, the device still has the power available to start connecting. If it was empty, it first had to charge to a certain voltage level. During this period it cannot operate as a tracker.

“Using SODAQ's technology, assets such as containers can be tracked anywhere in the world without having to worry about running out of battery power when there is no communication network coverage.”

Itay Dagan, CTO at SODAQ

What are the use cases?

For our patent-pending solution there a multiple use cases related to global shipments, such as:

- Global sea freight shipping: long-term allocating or passing through locations without connectivity

- Truck and container trackings, both on land and sea: shipments allocated in sheltered places without connectivity

An example case study:

A SODAQ TRACK with a shipment traveling from the Port of Rotterdam to Singapore. During its 25 days on the sea, it only has connectivity in the harbors, so it will only connect when it is relevant. Without the new solution on the TRACK, there would be a constant search for a network, draining the battery much faster than it should. But now, when the shipment arrives in Singapore, the TRACK still has enough power to connect and stay connected. Our test has proven this solution to be 130 times more efficient compared to the existing network sensing.

Benefits

- Check for network before connecting for maximum battery performance and low-power devices

- Detect location by the band: check for specific band and jump between bands

- Fast response time (approx. 2 seconds). Send a message as soon as you have a signal.

- Detect specific networks (like ADS-B of the airplane to know you are inside) to be airplane certified

A future without placing batteries

Our new solution will have positive consequences for the future of supply chain management. Dagan gives a sneak peek of what this will be like: “IoT trackers will be able to operate in any environment without the need to replace batteries, utilizing all necessary power from their surrounding energy sources: sunlight and radio waves. This will make IoT devices more sustainable as significantly fewer battery raw materials will be needed to support continuous tracking functions.”

Want to know more?

If you are interested in knowing more about this new solution, get in touch today at sales@sodaq.com.