Imagine a smart tracking device that delivers location-specific, supply-chain data on demand. Now picture that same device, but paper-thin. That is the Smart Label, the world’s thinnest shipment tracker, invented and designed by SODAQ Engineering.

The actual story behind the Smart Label starts in 2018, when SODAQ’s founder and co-founder of Booking.com, Jan Willem Smeenk, was approached by Bayer AG, the largest pharmaceutical and biotechnology company in the world.

Bayer is shipping products all over the world in boxes, bottles, tanks and containers. Each of these shipments can have a value of several hundreds or thousands of euros. The global corporation encountered different challenges with regard to these shipments, such as boxes that never reached their destination, or were sent back unused. This occasionally resulted in great losses for Bayer. For this reason, they were looking for a universal tracking solution that could be easily applied to any form of shipment.

Different options were tested looking for a solution and Bayer soon discovered that attaching a tracking device to the outside rather than the inside of a shipping box was the most effective way to track any product. This was because inserting an electronic device inside a container often causes delays with customs clearance during the logistics process. At the same time, Bayer recognized that placing a tracker on the outside of a box could also cause difficulties during the logistic process, as this would require the label to be as thin as possible. Fortunately, they knew about a German manufacturer that produced printed batteries, and this led to the idea of a shipping label with tracking capabilities powered by a battery. Bayer then decided to approach SODAQ, as the leader in low-power IoT, to request the development of the technology that could make this a reality. Several months later, we invented the Smart Label. An innovation that would revolutionize the way tracking would be done.

“Bayer told us that once they put a matchbox size tracker inside a valuable parcel, it was held by customs. The parcel never made it to the final destination, as it contained an undeclared item (the tracker). The easiest solution for this issue seemed to be simple: Don't put the tracker in the box, but stick it on the box. This is how the idea of a Smart Label arose.”

Jan Willem Smeenk

“After scanning the global IoT ecosystem, we found SODAQ to be the only party that could develop such low-power electronics that they could run on a 100mAh battery and be able to send up to 1000 messages over the mobile network. Until today, SODAQ is a unique and trusted supplier for innovative solutions at Bayer.”

Christof Backhaus

Developing the Smart Label

SODAQ started developing the Smart Label with Elmeric, a German producer of printed electronics and batteries. Together, we developed the first concept and a prototype was tested globally. Based on the findings, improvements were made that benefited the overall process and product, such as the use of a flex PCB (Printed Circuit Board) instead of a regular PCB. For the final production, SODAQ and Bayer initially collaborated with chip producer, Sony Altair, and connectivity provider, Vodafone. With the help of these companies, SODAQ and Bayer are pushing the concept towards a mass market product release with several manufacturers and telecom providers.

As of 2022, SODAQ is developing different types of Smart Labels for two global organizations that will be launched within the coming 6 months.

Functions of the Smart Label

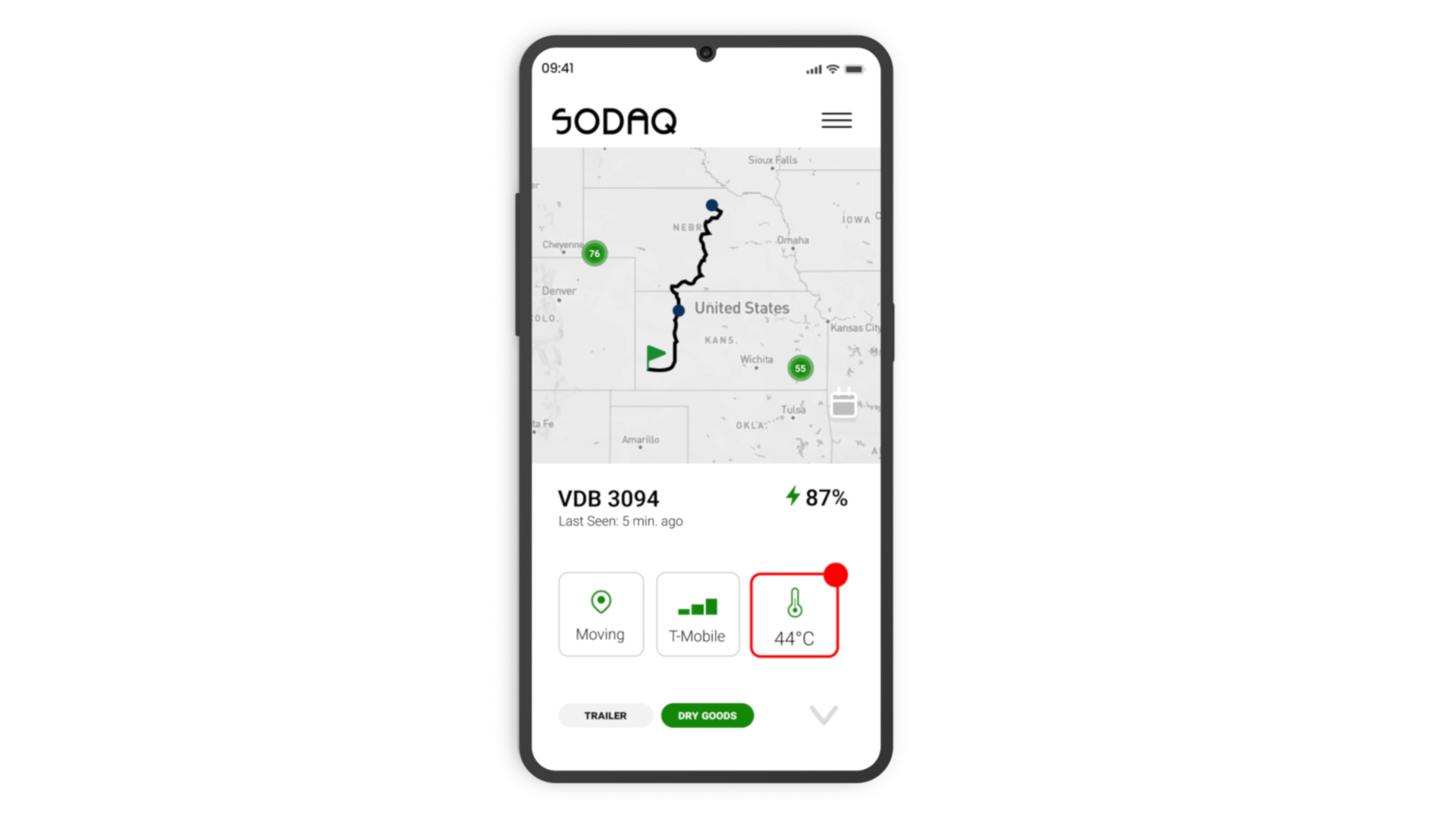

While the original Smart Label looks like a regular shipping label, it has been upgraded with leading technology. It allows organizations to follow their assets at any time, from anywhere. In addition, it is activated by cutting off the corner and attaching it to a single product, such as a letter, a parcel, or a container. From that moment, the Label functions up to 3 months. During that time, the Label allows a client to track the location of their assets from the moment they are shipped to the time they reach their final destination. At all times, the client can see whether their assets are in motion, or not. If the shipment is not in motion, there is no need for the Label to send any messages, thereby saving energy.

Further advantages are that it measures whether assets are tilted or upside down and a built-in temperature sensor tells a client what the temperature of their package is and if action is needed, in the case that a package is outside of the normal temperature range. The Smart Label’s final valuable function is that it is able to register the opening of assets, thanks to a circuit that sends a signal as soon as it is broken by opening the package. In this way, a client can see exactly when and where the package is opened.

World-friendly tracking labels

At SODAQ, our main mission is to develop products that contribute to a better world. Over the last years, we have continued developing the Smart Label into a new version that is wirelessly rechargeable and can be reused time after time: The SODAQ LABEL. A reusable Smart Shipping Label upgraded with additional wifi for more specific location tracking, temperature sensor and motion detection, giving organizations all details about their shipment’s journey. Offering a multi-use solution, the SODAQ LABEL can simply be added to the shipping pouches and tracks shippings as small as letters, and as large as boxes. It is designed with better and less harmful components and carries a thin supercapacitor, instead of a battery that enables it to be reloaded in just 10 minutes for 3 months of usage. This speedy, resilient reloading makes the SODAQ LABEL perfectly suitable for long-term reusability: within a closed-loop supply chain, it can continuously be used by all parties involved. With more control, clients can minimize waste, protect content integrity, reduce costs and provide greater value to end-users.

Need a Smart Shipping Label?

Does your company need a Smart Shipping Label? SODAQ is ready to develop it with and for you. Tell us all about your needs and wishes and we will tell you all about the possibilities.

Get in touch today through sales@sodaq.com.