The Journey of a Cellular Connected Label

– May 2023

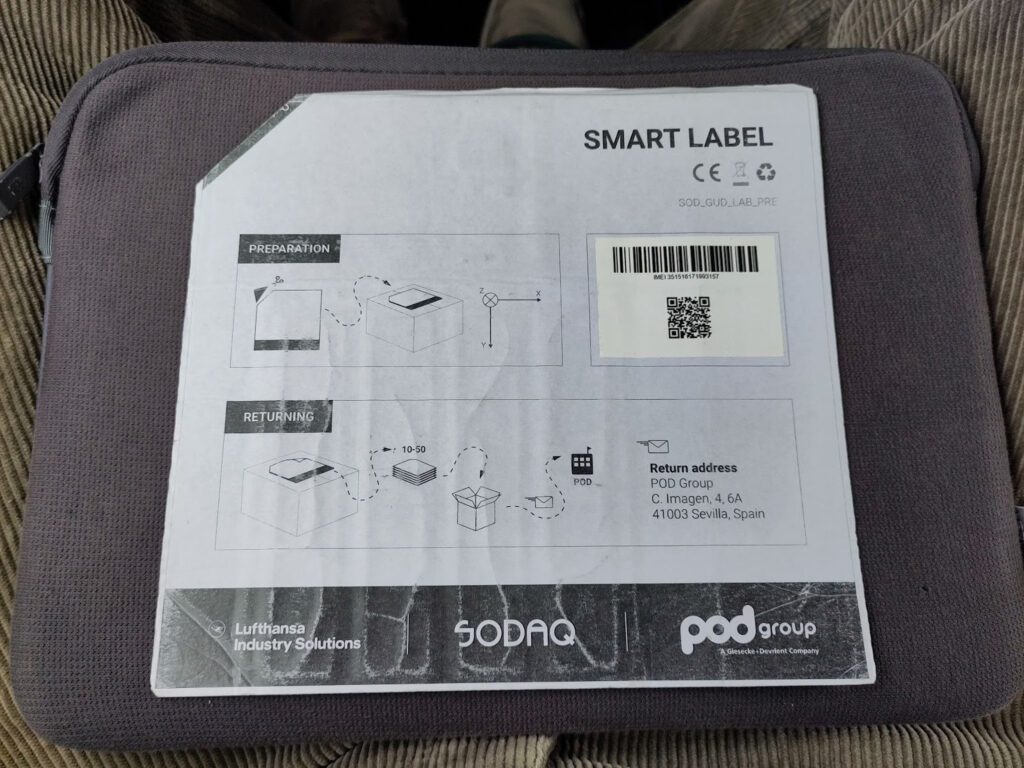

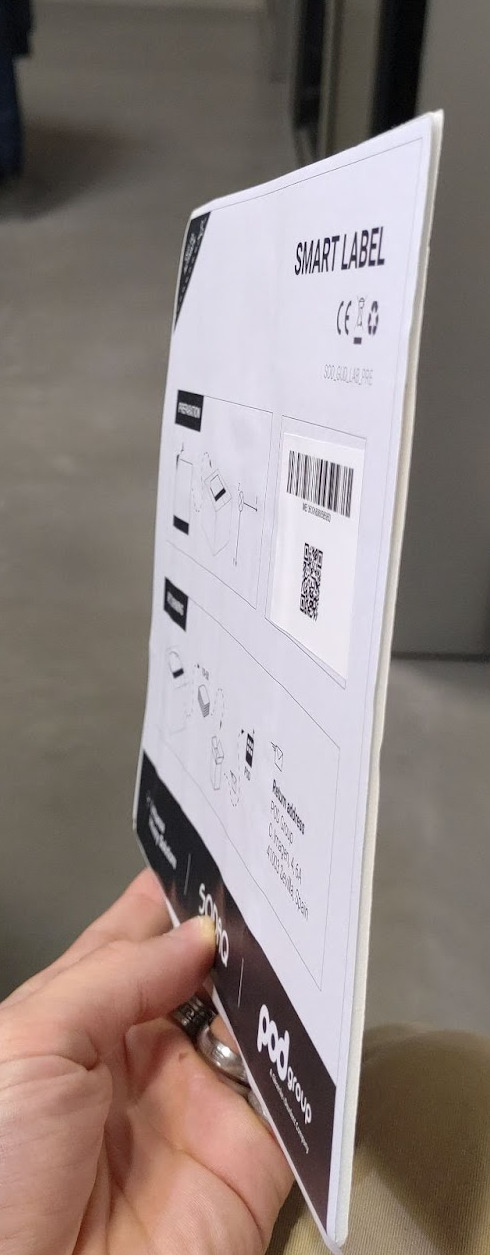

Since the initial request to build a paper-thin, mobile network connected device capable of detecting temperature and motion while tracking location, SODAQ’s engineers have worked tirelessly to create a product that maximizes the value of every mAh in the battery. This article will detail how SODAQ’s unmatched product development expertise has helped us to become one of the global leaders in low-power IoT.

While electronic components such as antennas and chips tend to be slim, batteries are often bulky, particularly when they need to provide the high peak currents necessary for transmitting messages over a public radio network, such as that provided by a mobile network operator.

Alongside our research and development efforts in flexPCB, antenna design, and software, several companies have pioneered battery printing techniques, based on the premise that achieving high peak-currents typically requires a lot of volume. However, with the right chemistry and larger surface area, this can also be achieved in a thin, wide, and long battery “sheet,” rather than a compact box shape or cylinder. To minimize thickness and optimize performance, a flexPCB and printed antenna can be placed beside the battery instead of on top. This approach represents truly innovative thinking. Nevertheless, the laws of physics dictate that a small battery volume inevitably results in low capacity. For our cellular smart label batteries, we have therefore chosen a 100mAh capacity. To put this in perspective, it is approximately 1/30th of the capacity of a typical smartphone battery (3000mAh).

With a battery capacity of only 100mAh, it was crucial to select a modem that could efficiently convert power into sending sensor and location data to the cloud. After extensive research, we ultimately chose the Nordic NRF9160 for its outstanding performance. In fact, it delivers twice the efficiency of the next best option.

While choosing the optimal modem was a significant step, it did not mean that we had achieved our goal. We still needed to dedicate approximately two years to developing and globally testing a complete solution that met our exact standards. Our embedded software, in particular, sets us apart from the competition.

To minimize power consumption, our most effective tool is trigger-based communication, which allows us to selectively enable or disable communication as needed. For this, we employed two sensors:

- With the help of the accelerometer, we can detect motion and keep the device in deep sleep until it needs to wake up. By using intelligent algorithms, we can transmit data at specific intervals when the device is in motion and at different intervals when it’s not. We can also trigger messages under more complex conditions, such as after a certain amount of movement or after remaining stationary for a set period. Through these mechanisms, we have developed what we call the “inverse flight mode“, which ensures compliance with aviation regulations when transporting our smart label.

- By leveraging the modem’s network scanning capability, we can quickly test for network availability and avoid wasting valuable battery capacity on attempting to connect to every available network. Scanning also allows us to determine the available radio access technology (RAT), such as LTE-M or NB-IoT, as well as the available operator. By attempting to connect only when a network is available, we can save a significant amount of battery capacity.

- To further optimize this process, we have developed a technology that performs the network scan passively instead of actively, which means it doesn’t consume any battery power to determine network availability. The method involves capturing ambient radio frequency radiation energy, filtering it through a matching circuit, and forwarding the energy only if it falls within a specific radio frequency range. If enough energy is harvested, a switch is activated, causing the device to turn on and start scanning for networks. While the data collected is not as detailed, it can inform us if a cellular LPWAN network is available within a certain frequency range. This approach, known as “antenna as a sensor,” is the only viable form of long-range radio frequency (RF) energy harvesting at present. It’s important to note that this feature is not yet available in the smart label.

Moreover, what sets us apart from the competition, is that we don’t mindlessly follow industry standards such as LWM2M or MQTT to transmit data. The overhead of these protocols is simply too high. Instead, we rely on simple binary messages over UDP, which are perfectly secure when we use cellular networks and a VPN to establish a secure connection to the cloud.

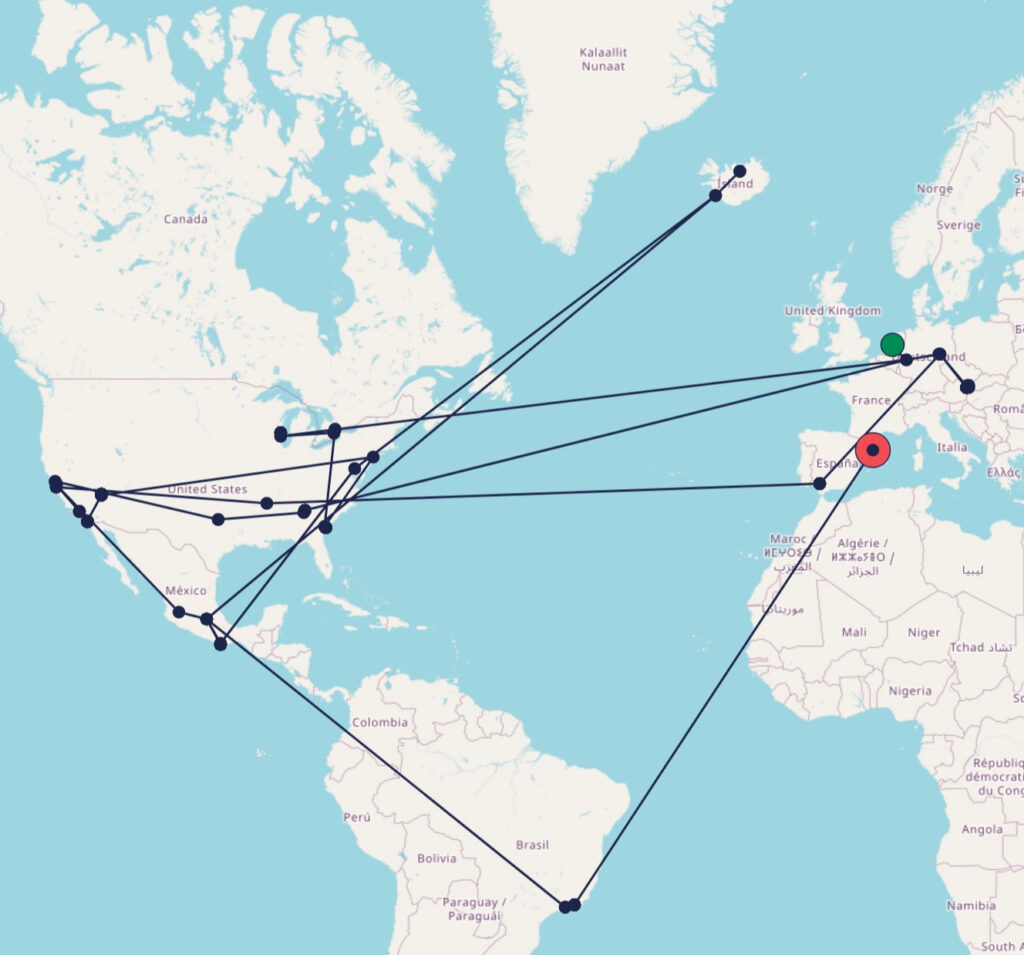

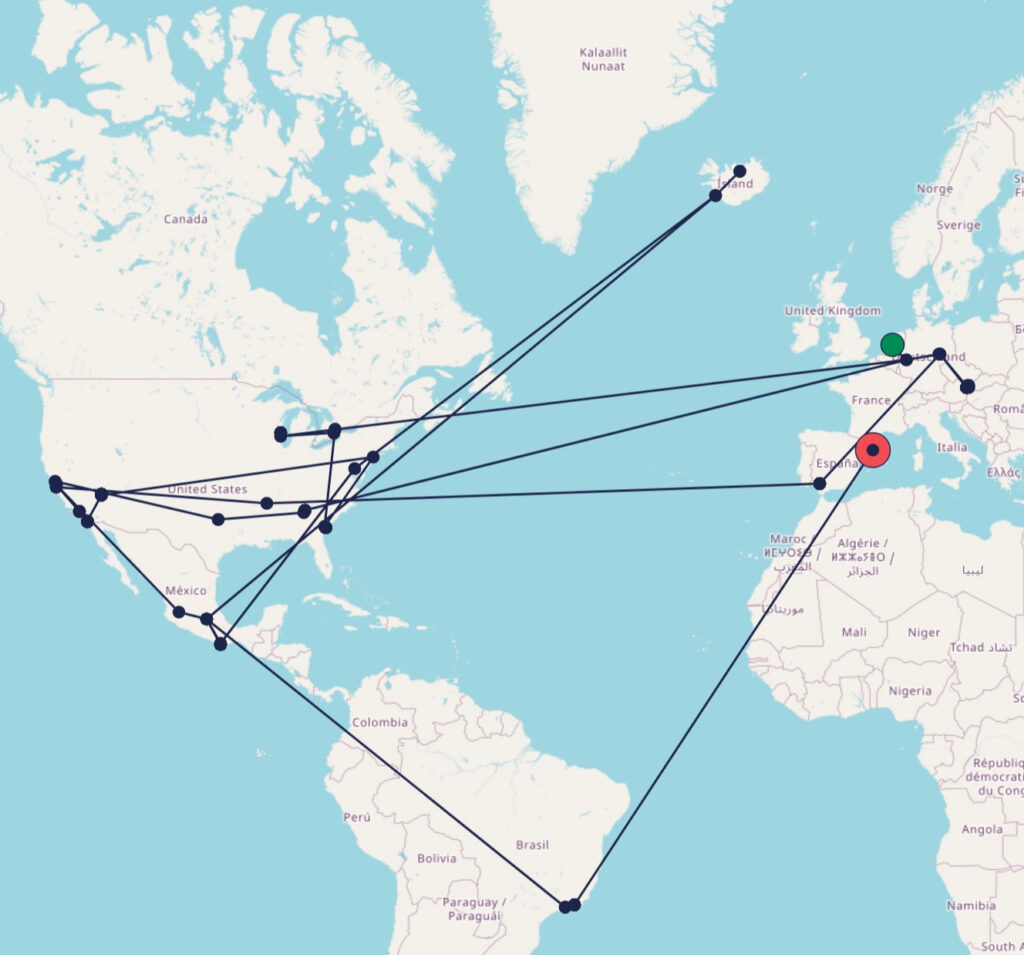

With this technology and the correct configurations, we have been able to send over 49,416 messages using 1,158 labels that traveled intercontinental and switched between operators in different countries. The image below shows a successful label test that started in November 2022 and is still ongoing today.

It has done 6 Atlantic crossings on a single printed battery. 535 messages and a modem-on-time of 8257 seconds. The battery is still at 4.5V, meaning it has around 20% capacity left, which is utterly amazing!

Jan Willem Smeenk, Co-Founder & Seniour Solution Architect

It implies that many connections to new network providers were successfully established; that the hardware and software are set in such a way that it works on many different frequencies in many regions.

Kees Hogenhout, Hardware Team Lead & Principal RF Engineer

However, it is important to note that this success was achieved after shipping hundreds of labels internationally, each with different configurations for RAT selection, accelerometer triggers, quick scan usage, and timeout length for network connection attempts. These labels were sent for different customer business cases, and their successful operation demonstrates the flexibility and adaptability of our technology to meet diverse needs.

Through these tests, we have found that there is no single set of optimal configurations. Depending on the needs of the user, we would recommend selecting a preset of configurations that either maximize the label lifetime or maximize the chance of successful delivery of each message. Either of these requires different RAT, time-out, and accelerometer settings.

In conclusion, after a long and ongoing journey across the world and through multiple research and development cycles, SODAQ’s engineers have mastered how to squeeze the most juice out of just 100mAh of battery capacity. The superior performance of our smart label has been attested by numerous clients and is regarded as one of the best in the market. Our modem supplier Nordic have even stated: “At SODAQ’s current position with the Smart Label, we believe they are at least 1-2 years ahead of the competition.” Through our tests, we have established that no combination of components can outperform this solution.

Besides this, our expertise in low power consumption has enabled us to develop tiny devices that use kinetic or solar energy harvesting, eliminating the need for battery replacements, allowing perpetual operation, and opening up opportunities in the world of supercapacitors.

More coming soon..