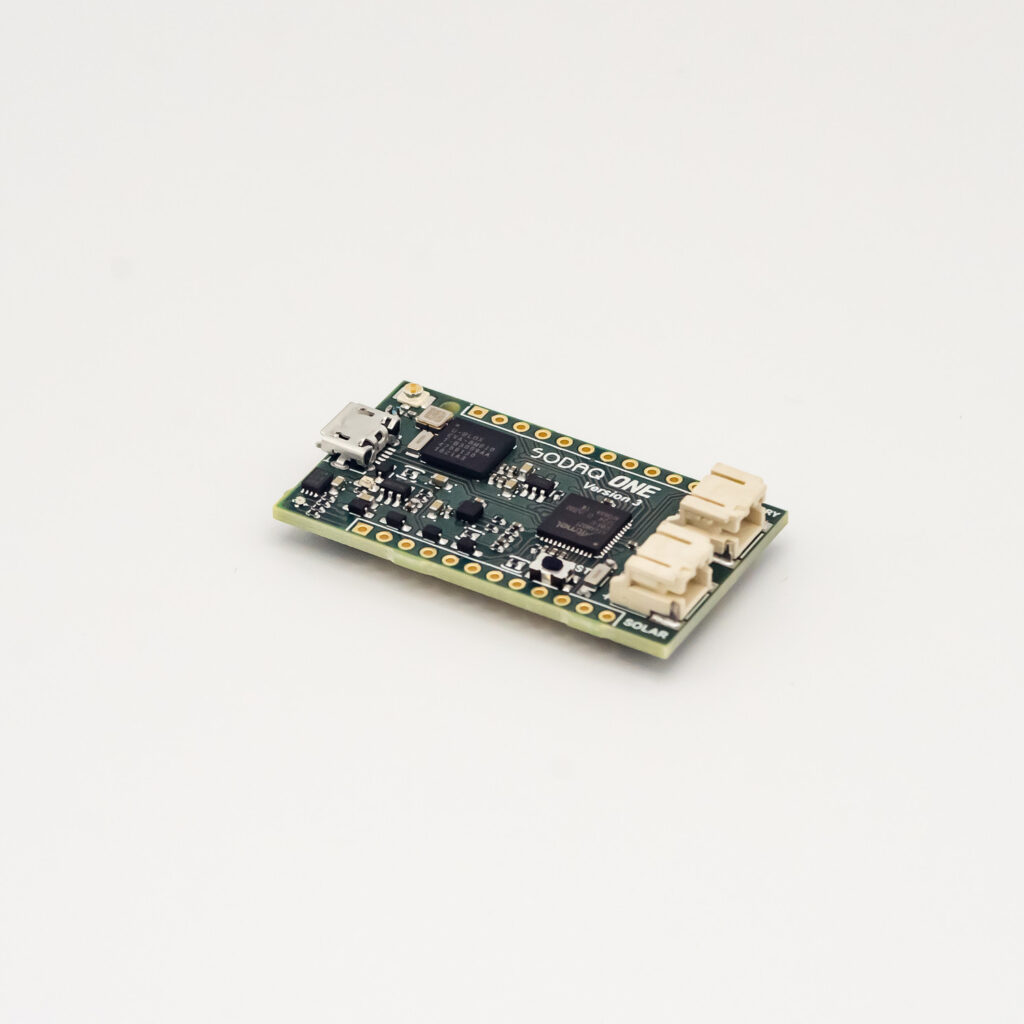

SODAQ Low power development boards

Challenge

To develop a low-power development board that could be implemented in a large range of sensors, while offering a wide range of connectivity options.

Outcome

A line of low-power development boards that enable a variety of sensors to connect to a multitude of low-power connectivity modules such as Sigfox, Zigbee, GPRS, and LoRa boards (in other words; low-cost IoT).

Impact

Our boards allow developers to create low-power IoT solutions with Sigfox, LoRa, NB-IoT, and LTE-M networks without a major investment or steep learning curves.

Why development boards?

When SODAQ first started, one of our main projects was developing weather stations. We were experienced with Arduino, however, we wanted a device that was more energy-efficient and lower in cost than was possible to create with the development boards that were on the market at the time. This led to the development of the SODAQ Moja, which evolved into a low-power hardware ecosystem for developers. With the SODAQ Moja, we wanted the flexibility of connecting a large range of sensors to different connectivity options (e.g. GPRS, LoRa, Sigfox, Zigbee). The development boards give the flexibility to set up a quick demo or proof of concept.

This has helped us and our clients to go from concept to product in a very short timeframe. With the ever-changing nature of the IoT industry, the boards also give us more flexibility as it allows for quick modification of designs to be able to work with different components or technologies.

The engineering process

With our development boards, the initial engineering focus is on our hardware process. We start by setting specifications and then begin working on the schematics and layouts. Initially, we worked in Eagle, like many major development companies, as it gave us the flexibility of easily sharing the design and implementations. However, recently we’ve moved to Altium Designer as it is better suited to the size of our teams and the continuous development of our engineering process.

After finalizing the design we manufacture the prototypes (in-house or externally), which underwent thorough testing. Based on the results we would redesign if needed, manufacture, and test again. After concluding our verification with satisfactory results, we communicate with our EMS partner and produce larger batches that can be sold.